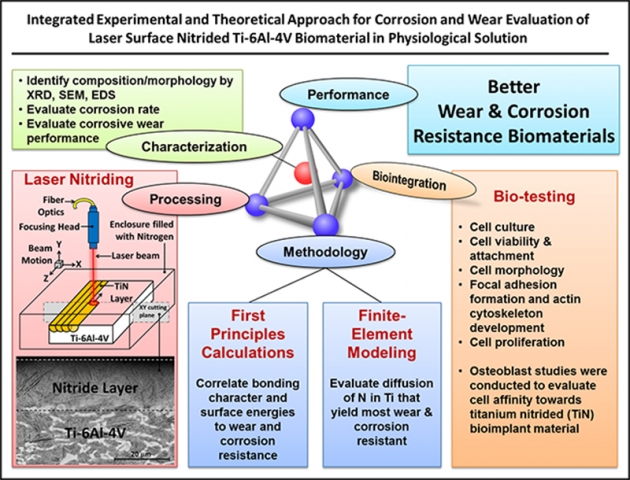

A laser based surface modification technique was successfully employed to nitride Ti-6Al-4V bioimplant material for improved biomedical properties. The main objective of these studies are to enhance the osseo-integration, corrosion resistance, and tribological properties of the commonly used bioimplant alloy, Ti-6Al-4V. A novel integrated experimental and theoretical approach (Figure 1) were developed and implemented to understand the physical phenomena behind the improvements and establish the property-structure-processing correlation of laser nitrided Ti-6Al-4V surface.

A multiphysics computational model was developed to mimic the laser nitriding process under various processing conditions and to predict the depth of TiN layer. The evolution of various phases, detailed microstructural investigation, and assessing the concentration of nitrogen were also conducted through x-ray diffraction (XRD), scanning electron microscopy (SEM), and energy dispersive spectroscopy (EDS) observations/analyses. The other objectives of this work were to: (i) explore the corrosive wear characteristics of laser nitrided surface by pin-on-disc sliding in simulated body fluid (SBF) with conditions as similar to that of orthopedic surgery; (ii) investigate the biomedical characteristics caused by laser nitriding through the medium of electrochemical testing; and (iii) study the growth characteristics of osteoblasts on laser nitrided substrates by following the standard protocol to evaluate biocompatibility.

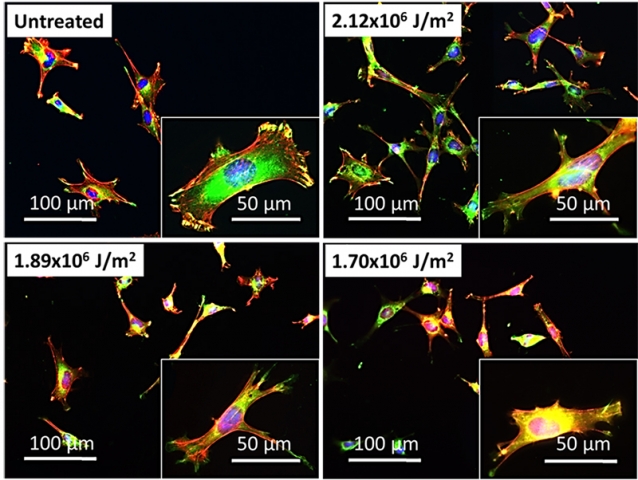

Furthermore, the first principle and thermodynamic calculations were employed to understand the thermodynamic, electronic, and elastic properties of TiN for enthalpy of formation, Gibbs free energy, density of states, and elastic properties of TiN were investigated. Additionally, open circuit potential and cyclic potentio-dynamic polarization tests were carried out in simulated body fluid to evaluate the corrosion resistance that in turn linked with the experimentally measured and computationally predicted surface energies of TiN. Preliminary osteoblast, electrochemical, and corrosive wear studies of laser nitrided titanium in simulated body fluid clearly revealed improvement of cell adhesion (Figure 2) as well as enhancement in corrosion and wear resistance. It is also concluded that the enhancement in the corrosion resistance after laser nitriding is mainly attributed to the presence of covalent bonding via hybridization among Ti (p) and N (d) orbitals. Furthermore, mechanical properties, such as, Poisson’s ratio, stiffness, Pugh’s ductility criteria, and Vicker’s hardness, predicted from first principle calculations were also correlated to the increase in wear resistance of TiN.

All the above factors together seem to have contributed to significant improvement in both wear and corrosion performance of nitride surface compared to the bare Ti-6Al-4V in physiological environment indicating its suitability for bioimplant applications. The microstructural and phase observations, corrosion evaluation, and cell behavior analysis of laser nitrided surface of bioimplant material (Ti-6Al-4V) indicated that laser based surface treatment is highly effective in treating bioimplant material for improved performance in physiological environment. Further, the laser, due to its unique physical and optical characteristics lends itself to precise, rapid, and automated processing of bioimplants.

Related Publications by the Group

- “Integrated Experimental and Theoretical for Corrosion and Wear Evaluation of Laser Surface Nitrided Ti-6Al-4V in Physiological Solution.”, Hitesh D. Vora, Ravi Sanker Rajmure, Sanket N. Dahotre, Yee-Hsien Ho, Rajarshi Banerjee, Narendra B. Dahotre, Submitted in Journal of the Mechanical Behavior of Biomedical Materials, 2014, 37, 153-164.

- “Laser Induced Nitrogen Enhanced Titanium Surfaces for Improved Osseo-integration: Experimental and Computational Methodology.”, Sanket N. Dahotre, Hitesh D. Vora, Ravi Sanker Rajmure, Lu Huang, Rajarshi Banerjee, Wei He, Narendra B. Dahotre, Annals of Biomedical Engineering, 2013, 42 (1), 50-61.

- "An Integrated Experimental and Numerical Approach to Laser Surface Nitriding of Ti-6Al-4V.", Sanket N. Dahotre, Hitesh D. Vora, Pavani Kami, Rajarshi Banerjee, Applied Surface Science 2013, 271, 141–148.