Magnesium alloys are the potential degradable materials for load-bearing implant application due to their comparable mechanical properties to human bone, excellent bioactivity, and in vivo non-toxicity. However, for a successful load-bearing implant, the surface of bio-implant must allow protein absorption and layer formation under physiological environment that can assist the cell/osteoblast growth. In this regard, surface wettability of bio-implant plays a key role to dictate the quantity of protein absorption. In light of this, the main objective of the present study was to produce favorable bio-wettability condition of AZ31B Mg alloy bio-implant surface via laser surface modification technique under various laser processing conditions. In the present efforts, the influence of laser surface modification on AZ31B Mg alloy surface on resultant bio-wettability was investigated via contact angle measurements and the co-relationships among microstructure (grain size), surface roughness, surface energy, and surface chemical composition were established. In addition, the laser surface modification technique was simulated by computational (thermal) model to facilitate the predication of temperature and its resultant cooling/solidification rates under various laser processing conditions. These predicted thermal properties were later used to correlate with the corresponding microstructure, chemical composition, and phase evolution via experimental analyses (XRD, SEM, EDS).

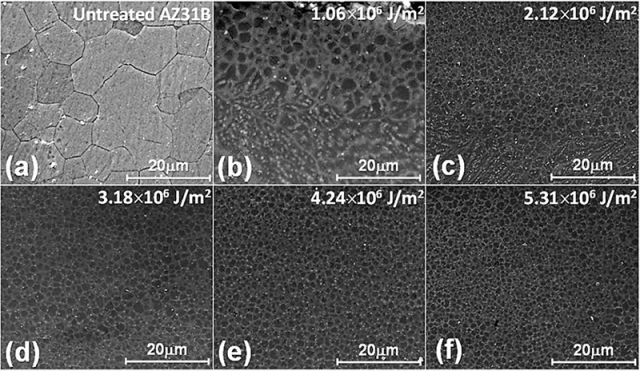

Laser surface modification can generate very high rate of heating and cooling/quenching, which in turn, increases the nucleation density and grain growth rate. Self-quenching is one of the unique features of laser surface modification, in which the small localized surface experiences rapid melting and solidification, while the bulk material below the surface serves as a heat sink with no change in microstructure. Thus, unique characteristics of laser heat treatment generate a fine-grain microstructure and promote phase transformations that are not possible using conventional techniques. As evidence, the cross-sectional SEM observation of laser treated samples (Figure 1) demonstrated such grain refinement. The Figure 1 shows the grain size variation of untreated and laser treated AZ31B Mg alloy samples.

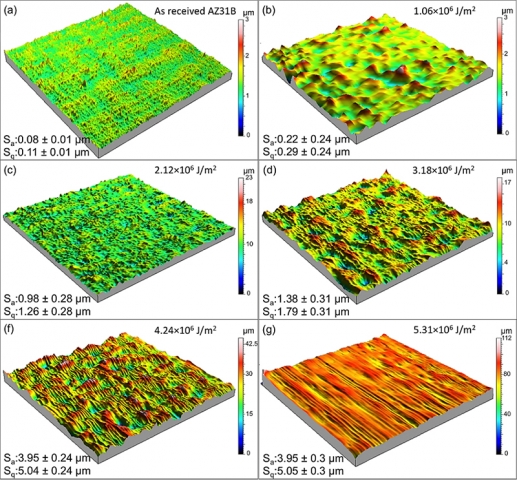

The optical profilometer was utilized to measure the surface roughness of the laser treated and untreated AZ31B Mg alloy and the corresponding three-dimensional surface morphology (Fig. 6). In order to quantify the degree of roughness, Fig. 2 shows the roughness parameters of all samples in area arithmetic mean height (Sa) and area root mean square height (Sq). The untreated AZ31B Mg alloy sample demonstrated the smoothest surface finish (Sa = 0.08 ± 0.01μm and Sq = 0.11 ± 0.01μm) (Fig. 6a). It was revealed that the surface roughness of laser treated samples increased with an increase in the laser energy density (Figure 2).

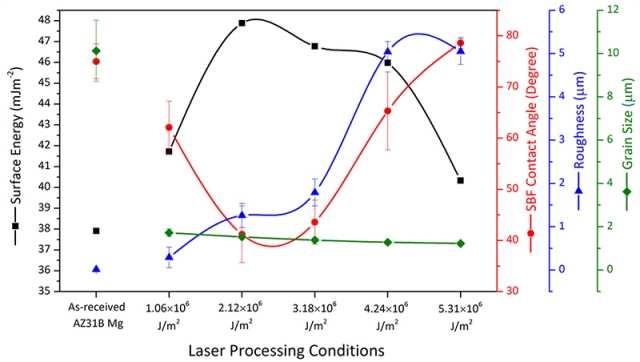

Furthermore, the bio-wettability is a complex phenomenon; several factors affect the interactions between bio-molecule and surface. It is also difficult to justify which factor plays as a predominant effect on surface wettability. Therefore, the bio-wettability performance of laser treated AZ31B Mg alloy surface is not only solely affected by the SBF contact angle values but also influenced by the surface characteristics such as average grain size and surface roughness (Figure 1 and 2). In order to investigate these correlations, the Figure 3 was prepared to demonstrate the trend of changing SBF contact angle, average grain size, surface roughness, and surface energy values. Comparing to the untreated AZ31B, the SBF contact angle of laser treated sample reduced with an increase in laser energy density, and it also corresponds to the trend of the increasing surface energy.

In conclusion, this enhancement in bio-wettability for laser surface modification AZ31B Mg alloy can therefore be attributed to the combine effect of grain size, roughness, and surface chemistry following laser processing. Related Publications by the Group

- “Laser Surface Modification of AZ31B Mg Alloy for Bio-Wettability”, Y-H Ho, H.D. Vora, Narendra B. Dahotre, Journal of Biomaterials Applications, June, 9, 2014.

- “Macro and Microstructural Study of Laser Processed WE43 (Mg-Y-Nd) Magnesium Alloy”, S. Santhankrishnan, N. Kumar, N. Dengde, D. Chaudhuri, S. Katakam, S. Palanivel, H.D. Vora, R. Banerjee, R.S. Mishra, and Narendra B. Dahotre, Metallurgical and Materials Transactions B, Vol. 44, Issue 5, pp: 1190-1200, 2013.

- “Laser coating of hydroxyapatite on Mg for enhanced physiological corrosion resistance and biodegradability”, S. Santhanakrishnan, Y. H. Ho and N. B. Dahotre, Materials Technology.

- “Pulsed Laser Surface Modification of AZ31B Mg with Al-Si”, Baoshuai Du, Sameer R. Paital, and Narendra B. Dahotre, Surface Review and Letters, Vol. 19, No. 02, (2012) 1250015.

- “Improved Corrosion and Wear Resistance of Mg Alloys via Laser Surface Modification of Al on AZ31B”, Sameer R. Paital, Ananya Bhattacharya, Marco Moncayo, Yee Hsien Ho, Kristopher Mahdak, Soumya Nag, Rajarshi Banerjee, Narendra B. Dahotre, Surface Coating & Technology, Vol. 206, No. 8-9, pp. 2308-2315, 2012.

- “Laser Surface Cladding of MRI 153M Magnesium Alloy with (Al+Al2O3)”, M. Hazra, A. K. Mondal, S. Kumar, C. Blawert, and Narendra. B. Dahotre, Surface and Coating Technology, Vol. 203, No. 16, pp. 2292-2299, 2009.

- “Pulsed Laser Surface Treatment of Magnesium: Correlation between Thermal Model and Experimental Observations” , Anoop N. Samant, Baoshuai Du, Sameer R. Paital, Subodh Kumar, and Narendra B. Dahotre, J. Materials Processing Technology, Vol. 209, No. 11, pp. 5060-5067,2009.

- “Effect of Laser Surface Treatment on Corrosion and Wear Resistance of ACM720 Mg Alloy”, A. K. Mondal, S. Kumar, C. Blawert and Narendra B. Dahotre, Surface & Coatings Technology, Vol. 202, No. 14, pp. 3187-3198, 2008.