Engineered artificial scaffold biomaterials with appropriate mechanical properties, surface chemistry and surface topography are in a great demand for enhancing cell attachment, cell growth and tissue formation at the defect sites. Most of these engineering techniques are aimed at mimicking the natural organization of the bone tissues and thereby create a conducive environment for bone regeneration. Hence, there has been a great thrust towards development of Ca-P based surface coatings on various metallic and non-metallic substrates for load bearing implant applications such as hip joint prosthesis, knee joint prosthesis and dental implants. In our group we aim towards synthesizing such textured Ca-P based coating with appropriate topographical cues and surface chemistry by a laser based coating technique. The advantages associated with the above technique are that both a 3-dimensional topographic cue and appropriate chemistry suitable for load bearing implant applications can be achieved by a single step process.

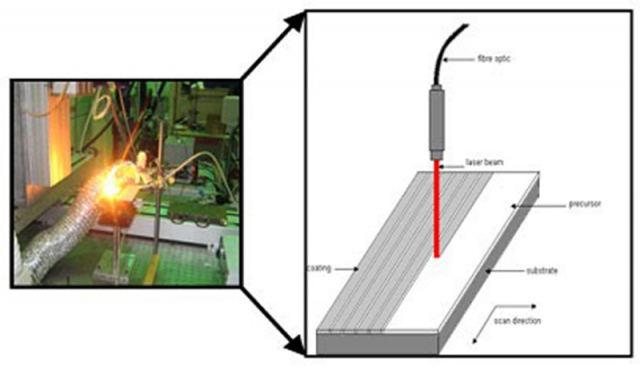

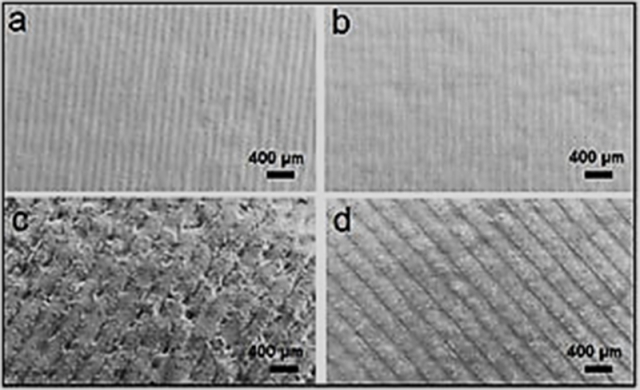

The Hydroxyapatite (Ca10(PO4)6(OH)2, HA) precursor powder was mixed in a water based organic solvent sprayed on the thoroughly cleaned Ti-6Al-4V plate. The sprayed components can then be scanned using a laser beam to achieve the textured coating. The actual processing window and the schematic of the coating process is illustrated in Figure 1. As the laser beam can be programmed to have different lateral spacing within the track, coatings with different textures (Figure 2) can be synthesized.

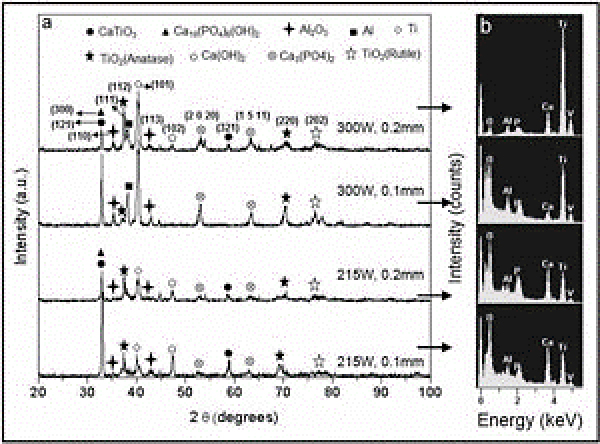

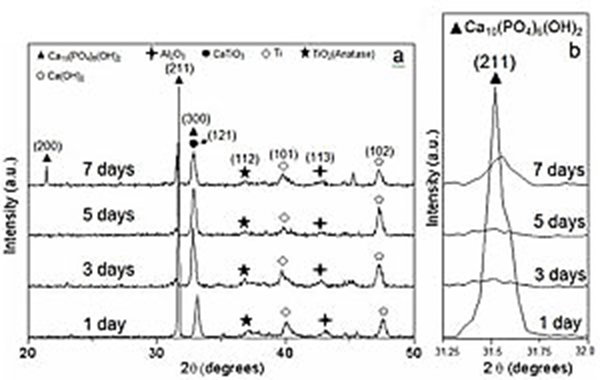

Further, with varying laser processing parameters (energy, average power, laser beam residence time, etc.) surfaces with appropriate chemistry (HA, CaTiO3, Ca3(PO4)2, TiO2 (Anatase), TiO2 (Rutile)) as observed from the X-ray diffraction (XRD) and energy dispersive spectroscopy (EDS) spectra (Figure 3) of the coated samples can also be synthesized.

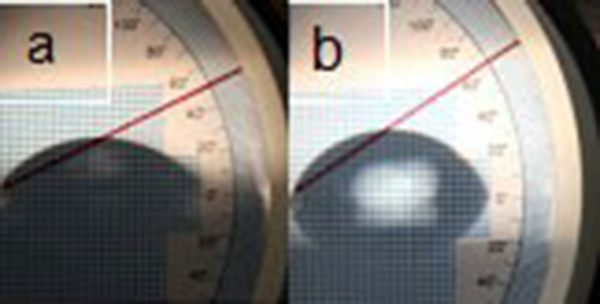

When an implant material is placed inside a human body, among the plethora of events that takes place, the first and the foremost one is the wetting of the implant material by thephysiologicalfluids. This further controls the absorption of proteins followed by attachment of cells to the implant materials. Also, as the surface chemistry and the surface morphology of the coatings influence the wetting behavior and there by the protein adsorption and cell attachment, an understanding of the wettability of these surfaces by contact angle measurements is also major focus of the group. Accordingly, these textured coatings have shown enhanced hydrophilicity of a test liquid (Figure 4a) compared to the untreated Ti-6Al-4V (Figure 4b).

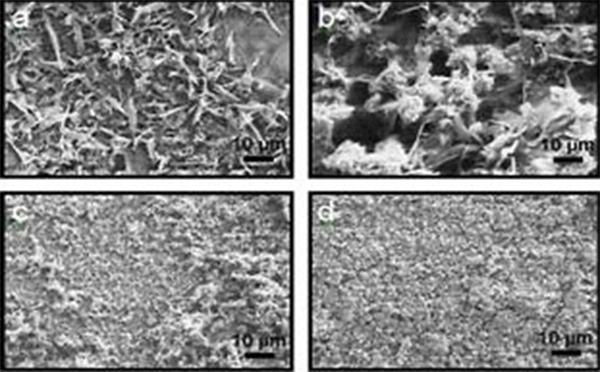

Since, HA is a naturally occurring mineral component of human bone laying alongside the collagen fibrils, the precipitation of such a phase on the coatings following immersion in a simulated body fluid (SBF), a solution with ion concentrations and pH value similar to those of human blood plasma, provides information pertaining to the in vitro bioactivity of the coatings. Further, as this layer provides the appropriate chemistry and there by acts as a bone bonding interface, where the cells can preferentially proliferate and differentiate into complex tissues such as bone, an understanding of the mineralizing ability of the coatings following immersion in SBF, has attracted us as it is a process similar to biological mineralization. The surfaces of textured coatings following immersion in SBF demonstrated precipitation of whisker-like apatite crystals (Figure 5 a) following 1 day immersion in SBF. As the immersion time was increased to 3 days the whisker-like feature is further covered by another mixed layer of whisker-like and nano HA crystals (Figure 5b). After 5 day immersion, the layer is completely covered with nano crystallites of HA (Figure 5c) and at the end of 7 days there is a thick mineralized layer of HA on the surface of the sample (Figure 5d). XRD studies of the SBF immersed samples further confirmed the mineralized layer to be of HA (Figure 6).

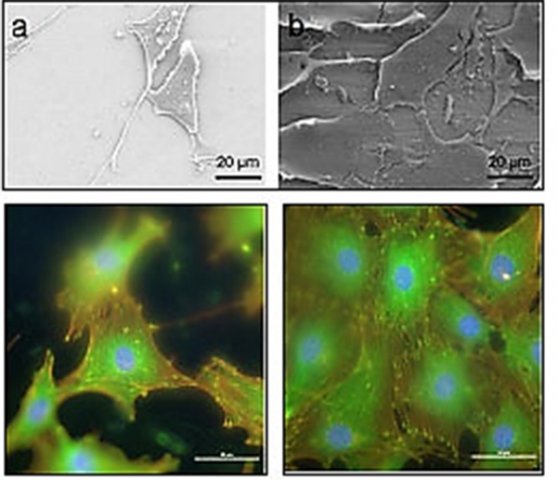

The in vitro biocompatibility of the coatings can be studied by the culture of mouse MC3T3-E1 osteoblast-like cells. The MC3T3-E1 osteoblast-like cells show a triangular morphology (Figure 7a) on the control (untreated Ti-6Al-4V) samples and have a rectangular and elongated morphology (Figure 7b) on the laser processed samples. Their sound adhesion, especially on the laser textured samples is characterized by the lamellipodia trying to extend and adhere along the grooves. In contrast, no such adhesion is observed on the control (untreated Ti-6Al-4V) sample (Figure 7). The cytoskeletal organization of the cells after 7 day culture demonstrated more confluence with well stressed actin filaments on the laser textured samples (Figure 7d) compared to the control (Figure 7c).

Related Publications by the Group

- “MC3T3-E1 Osteoblast Adhesion to Laser Induced Calcium Phosphate Coating on Ti Alloy: an In Vitro Centrifugation Study”, Lu Huang, Samuel Goddard, S. Soundarapandian, Yu Cao, Narendra B. Dahotre, and Wei He, Biofabrication, December 10, 2013.

- “Laser deposited Biocompatible Ca-P coatings on Ti-6Al-4V: Microstructural Evolution and Thermal Modeling”, Soumya Nag, Sameer R. Paital, Peeyush Nandawana, Kristopher Mahdak, Yee Hsien Ho, Hitesh Vora, Rajarshi Banerjee, Narendra B. Dahotre, Materials Science & Engineering C: Materials for Biological Applications, Vol. 33, Issue 1, pp: 165-173, 2013.

- “Laser coating of hydroxyapatite on Mg for enhanced physiological corrosion resistance and biodegradability”, S. Santhanakrishnan, Y. H. Ho and N. B. Dahotre, Materials Technology.

- “Osteoblast Interaction with Laser Cladded HA and SiO2-HA Coating on Ti-6Al-4V” Yuling Yang, Kaan Serpersu, Wei He, Sameer R Paital, and Narendra B Dahotre, Materials Science and Engineering C, Vol. 31, pp. 1643-1652, 2011.

- “Electrochemical and Mechanical Behavior of Laser Processed Ti6Al4V Surface in Ringers Physiological Solution”, Raghuvir Singh, S.K. Tiwari, Suman K. Mishra, and Narendra B. Dahotre, J. Materials Science: Materials in Medicine, Vol. 22, pp. 1787-1796, 2011.

- “Laser Surface Modification for Synthesis of Controlled Textured Bioactive and Biocompatible Ca-P Coatings on Ti-6Al-4V”, Sameer R. Paital, Nancy Bunce, Peeyush Nandwana, Chinmay Honrao, Soumya Nag, Wei He, Raj Banerjee, Narendra B. Dahotre, Journal of Materials Science: Materials in Medicine, Vol.22, No.6, pp. 1393-1406, 2011.

- “Wetting Effects on In-vitro Bioactivity and In-vitro Biocompatibility of Laser Micro-textured Ca-P Coating”, Sameer R. Paital, Zheng Cao, Wei He, Narendra B. Dahotre, Biofabrication, Vol. 2, No. 2, pp. 1-14, 2010.

- “Wetting and in Vitro Bioactivity of Laser Processed CaP Coating with Presence and Variation of SiO2 on Ti-6Al-4V” Yuling Yang, Sameer R Paital, Narendra B Dahotre, Materials Technology: Advanced Performance Materials, Vol.25, No.3-4, pp.137-142, 2010.

- "Laser Pulse Dependent Micro Textured Calcium Phosphate Coatings for Improved Wettability and Cell Compatibility", Sameer R. Paital, Wei He, Narendra B. Dahotre, Journal of Materials Science: Materials in Medicine, Vol. 21, No. 7, pp: 2187-2200, 2010.

- "Laser Process Effect on the Texture Evolution and Wetting Behavior in Implantable Ti-6Al-4V Alloys", Sameer R. Paital, Wei He, Claus Daniel, and Narendra B. Dahotre, Journal of Minerals, Metals and Materials Society (JOM), Vol. 62, No. 6, pp: 76-83, 2010.

- "Effects of SiO2 Substitution on Wettability of Laser Deposited Ca-P Biocoating on Ti-6Al-4V" Yuling Yang, Sameer R Paital, Narendra B Dahotre, Journal of Materials Science: Materials in Medicine, Vol. 21, pp. 2511-2521, 2010.

- "Fractal Approach to Laser Processed Surfaces", Anil Kurella and Narendra Dahotre, Advanced Engineering Materials, Vol. 12, Issue 6, pp: 517-521, 2010.

- "Wetting Behavior of Laser Synthetic Micro Textures on Ti-6Al4V for Bioapplication" Narendra B Dahotre, Sameer R. Paital, Anoop N Samant, and Claus Daniel, Philosophical Transactions of The Royal Society-A, Vol. 368, pp. 1863-1889, 2010.

- "Fabrication and Evaluation of Pulse Laser Induced Ca-P Coating on a Ti-alloy for Bioapplication", Sameer R. Paital, Kantesh Balani, Arvind Agarwal, and Narendra B. Dahotre, Biomedical Materials, doi:10.1088/1748-6041/4/1/015009.

- "Calcium Phosphate Coatings for Bio Implant Applications: Materials, Performance Factors, and Methodologies", Sameer R. Paital and Narendra B. Dahotre, Materials Science & Engineering - R: Reports, Vol. 66, No. 1-3, pp. 1-70, 2009.

- "Wettability and Kinetics of Hydroxyapatite Precipitation on Laser Textured Ca-P Bioceramic Coating", Sameer R. Paital and Narendra B Dahotre, Acta Biomaterialia, Vol. 5, No. 7, pp. 2763-27772, 2009.

- "Laser Surface Multilevel Self Assembly of CaP-TiO2 Particles," Anil K. Kurella, Anoop N Samant, and Narendra B Dahotre, Journal of Applied Physics, Vol. 29, No. 6, pp. 969-993, 2009.

- "Review of laser based biomimetic and bioactive Ca–P coatings ", Sameer R. Paital and Narendra B. Dahotre, Materials Science and Technology, Vol. 24, No. 9, pp. 1144-1161, 2008.

- "Effect of Microstructural Evolution on Wettability of Laser Coated Calcium Phosphate on Titanium Alloy", Anil K. Kurella, Michael Z. Hu, and Narendra B. Dahotre, Materials Science and Engineering -C: Biomimetic Materials, Sensors and Systems, Vol. 28, No. 8, pp. 1560-1564,2008.

- "Laser Surface Processing of Ti6Al4V in Gaseous Nitrogen: Corrosion Performance in Physiological Solution", Raghuvir Singh, S. Ghosh Chowdhury, S. K. Tiwari and Narendra B. Dahotre, J. Mater. Sci: Mater. Med., Vol. 19, pp. 1363-1369, 2008.

- "Laser Surface Treatment for Porous and Textured Ca-P Bio-Ceramic Coating on Ti-6Al-4V", Sameer R. Paital and Narendra B. Dahotre, Biomedical Materials, Vol. 2, pp. 274-281, 2007.

- "Tribological Behavior of Plasma Sprayed Carbon Nanotube Reinforced Hydroxyapatite-Coating in Physiological Solution", Kantesh Balani, Yao Chen, Sandip P. Harimkar, and Narendra B. Dahotre, Arvind Agarwal, Acta Biomaterialia, Vol. 3, pp. 944-951, 2007.

- "Corrosion Degradation and Prevention by Surface Modification of Biometallic Materials", Raghuvir Singh and Narendra B. Dahotre, J. Materials Science: Materials in Medicine, Vol. 18, pp. 725-751, 2007.

- "Laser Induced Hierarchical Calcium Phosphate Structures", Anil Kurella and Narendra B. Dahotre, Acta Biomaterialia, Vol. 2, pp. 677-688, 2006.

- "A multi-textured calcium phosphate coating for hard tissue via laser surface engineering ", Anil Kurella and Narendra B. Dahotre, Journal of Minerals, Metals and Materials Society (JOM), Vol. 58, No. 7, pp. 64-66, 2006.

- "Laser Induced Multi-scale Textured Zirconia Coating on Ti-6Al-4V", Anil Kurella and Narendra B. Dahotre, J. Materials Science: Materials in Medicine, Vol.17, pp. 565-572, 2006.

- "Laser Surface Modification of Ti-6Al-4V: Wear and Corrosion Characterization in Simulated Bio-fluids", R. Singh, A. Kurella, and Narendra B. Dahotre, Journal of Biomaterials Applications, Vol. 21, No. 1, pp. 46-72, 2006.

- "Tribology of Laser Modified Surface of Stainless Steel in Physiological Solution", R. Singh and Narendra B. Dahotre, J. Materials Science, Vol. 40, No. 21, pp. 5619-5626, 2005.

- "Review Paper - Surface Modification for Bioimplants: The Role of Laser Surface Engineering", Anil Kurella and Narendra B. Dahotre, Journal of Biomedical Applications, Vol. 20, No. 1, pp. 5-50, 2005.

- "Influence of Laser Surface Modification on Corrosion Behavior of Stainless Steel 316L and Ti6Al4V in Simulated Body Fluid" Raghuvir Singh, Madhavi Martin and Narendra B. Dahotre Surface Engineering, Vol. 21, No. 4, pp. 1-10, 2005.